Companies Join in Making Face Shields

May 12, 2020

A successful effort by a Richmond company to manufacture equipment to protect healthcare and emergency workers now involves three companies who are providing thousands of face shields to customers across the nation.

Doug Borgsdorf, Business Unit Director with Primex Plastics, says the effort’s updated tagline is “Houston, we have a new partnership!” He was referencing how the company described two weeks ago an “Apollo 13 moment” when his team looked at what Reid Health needed and then gathered up things they normally make on a table to figure out how to make face shields – and then doing so in two days. News of the effort spread and resulted in two more Richmond companies joining in to help in what has become a national effort.

Workers on the job at B & F Plastics

Ahaus Tool & Engineering, Inc., and B & F Plastics are also working with Primex to produce the shields, which have been ordered by more than 75 other healthcare systems. Borgsdorf notes this project is the first time the three companies have collaborated like this – before, they were suppliers or customers of each other.

“I think this really goes to the heart of small town USA and the drive of people working together in ways we probably never thought possible,” he said. “I’m so very proud.”

Justin Scheiben, Vice President at B & F, said his company was aware of the need for face shields and heard what Primex was doing for Reid Health, so the company offered to help. His company supplies products for several plastic and rubber markets and has seen a slowdown in the automotive and RV industry that was affecting his business. “We have been able to transition 12 employees into the die-cutting/fabrication part of this face shield process, which has helped in not having to cut hours or potentially lay-off anyone in this unexpected slowdown.”

In yet another community support moment, B & F also purchased a supply of the shields and donated them to local law enforcement agencies, including Richmond Police, Wayne County Sheriff’s and Reid Health Police.

Most of the companies’ current effort is to produce the more broadly used face shield that Primex developed for Reid, though the company is also making shields for a special protective helmet for Tacoma, Wash., hospitals.

At Ahaus, company officials say they were able to quickly develop a process to support Primex, with Ahaus team members assembling 75,000 to 100,000 masks a week. Jeff Sheridan, Vice President and Co-Owner, said the company has a dedicated production space with 12 assembly work stations along with other areas for staging materials and final packaging. “We have also adjusted some work schedules to get a partial second shift in place for assembly. This type of production is very different from our normal business of designing and building custom manufacturing equipment, so it has been a big adjustment for our whole team to get into a high volume production mode very quickly. I could not be more pleased with how our team has jumped in to help.”

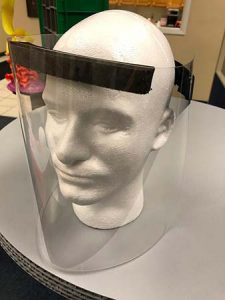

The face shield developed by Primex.

In what Primex officials dubbed their “Apollo 13 moment,” a chance connection a couple of weeks ago led to Primex figuring out how to make the shields for Reid in just two days. Brent Cotter, who is a manager in the Material Services department at Reid that deals with supplies, suggested to Scott Rauch, Reid Health Vice President, that a plastics company may be able to help. Rauch happened to attend a Bible study with Dale Blunk from Primex. That connection led to a meeting the next day and production in two more.

The reports on that effort spread the news, which led to orders coming in from across the country from hospitals struggling with a national shortage of protective equipment. Before the COVID-19 emergency, the company normally made returnable protective packaging.

Borgsdorf said his plants are now able to produce almost 350,000 face shields and 20,000 “bio helmet” shields a week.

Kevin Ahaus, President and Co-owner, says his team has a great attitude about the change, its partnerships and the challenges. “This production atmosphere is a challenge for our team, which is accustomed to designing and building custom equipment. The project should give many of us a renewed appreciation and understanding of how our equipment helps the overall process and lives of those making products on a daily basis. We are also very excited to be working with other companies in Richmond to help people serving on the front lines of this crisis. We know that the people of the community come together in times of need, and this moment is no different. We are honored to be a part of that.”