Compound Testing and Analysis

Compound testing and analysis

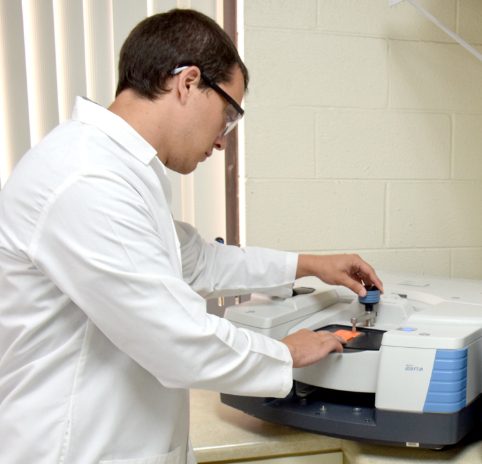

At our Jasper, Tennessee research and development lab, Primex experts work closely with customers to develop custom colors and plastic compounding solutions for product development and retroengineering.

- State-of-the-art testing and analysis equipment

- Expert polymer chemists, color specialists, and researchers on staff

- ISO 9001:2015 certified facility

- A2LA accredited laboratory

Capabilities

Our advanced testing platforms and processing equipment give us flexibility to evaluate physical properties and characteristics and develop smart plastic compounding solutions for the most complex applications.

Color Analysis

- Precision color matching

- Advanced lighting simulation

- Color measurement

- Color transmittance

- Custom formulations

- Instrumental color analysis

- Optical density

- Reflectance values

- Spectrophotometer analysis

Prototyping

- Tapes

- Color chips

- Molded test bars

- Sheet and thermoformed parts

Equipment

- DSC

- FTIR

- TGA

- QUV/Xenon Arc Weatherometer

Materials Testing

- Accelerated weathering

- Ash/carbon

- Conductance

- Density

- Density/specific gravity

- Feature enhancements

- Flow rate

- Hardness

- Impact strength

- Inspection

- Material evaluation

- Material identification

- Melting point, recrystallization, glass transition

- Moisture content

- Mono-layer material trials

- Opacity/transmission

- Peel strength

- Plastic compounding

- Surface defects

- Surface gloss

- Surface integrity

- Tensile, tear, flexural, compression, 90º peel, CoF

- Three-layer material trials

- UL94 flame testing

- Viscosity

- Wear/abrasion

- Weight

Ready to Talk?

We work with ambitious leaders who want to define the future, not hide from it. Together, we achieve extraordinary outcomes.

"*" indicates required fields