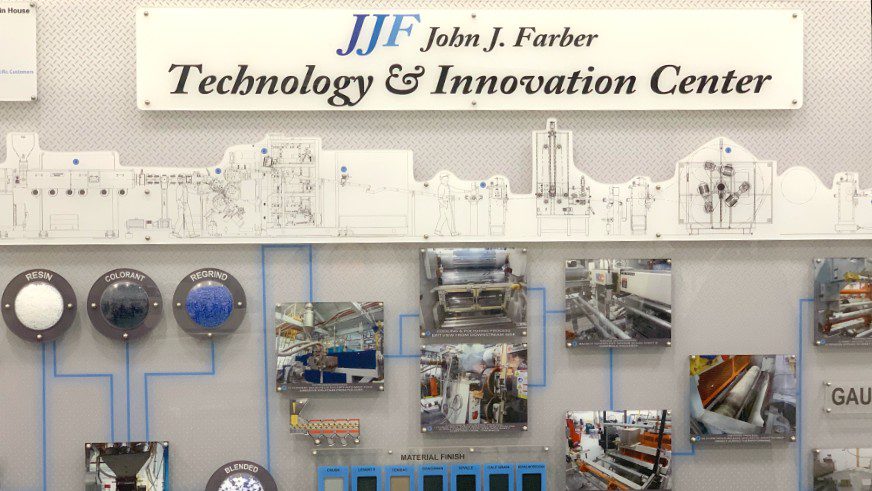

John J. Farber Technology & Innovation Center

Located at Primex Headquarters in Richmond, Indiana, our ISO/IEC 17025:2017 accredited testing lab drives research, development, and future-focused plastic solutions for our locations and customers worldwide.

Trials

Our technicians constantly evaluate new materials, additives, compounds, and sheet construction in support of our vendors, customers, and internal needs.

Testing

Using advanced equipment and protocols, our lab provides test support for each of our sheet plants in the United States and England, our Color, Compounding & Additives division, our Design & Fabrication division, and our ReCycling Operations program as well as vendors, customers, and clients.

Training

We design and deliver material and process training for Primex staff, as well as our vendors and customers worldwide. Each training module is tailored to unique audience needs.

Capabilities

Our ISO/IEC 17025:2017 accredited testing lab, advanced equipment, and experienced technicians give us the flexibility and capacity to deliver outstanding results and custom solutions fast.

Accreditation

- Scope of Accreditation to ISO/IEC 17025:2017

- A2LA accredited testing lab, certificate number 4071.01

Approach

- Independent from manufacturing

- Troubleshooting and root cause analysis

- Service-driven

- Unbiased research

Capacity

- Analytical analysis

- Mechanical analysis

- Raw material and product testing

- Dedicated R&D lines

- Fast scale-ups

- Product and solution development

- Thermal cycling

- Accelerated weathering

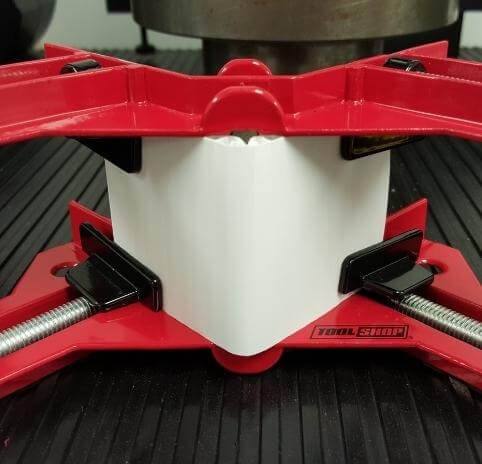

Trials

- Extrusion

- Forming

- Large scale production trials

- Lot Testing

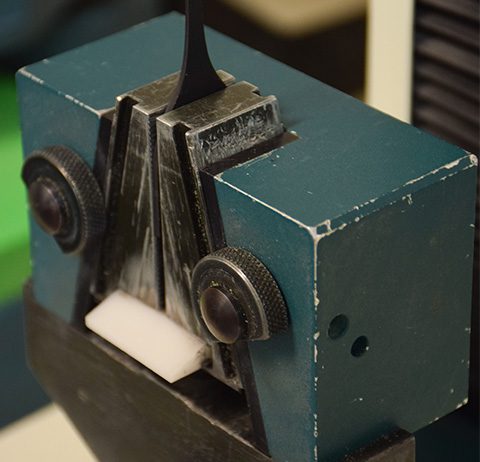

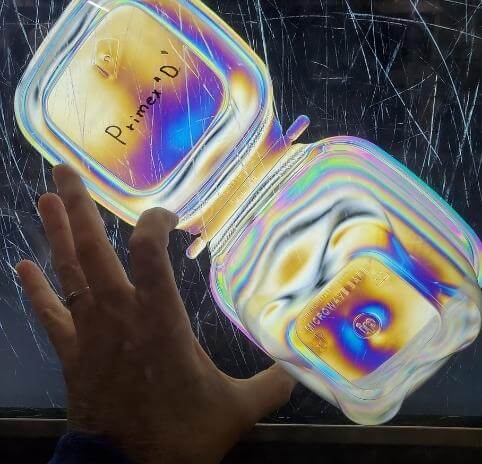

Testing

Because of our A2LA accredited testing lab status, we are able to offer a wide range of testing options for our vendors and customers. We work with you to identify the right approach to meet your needs and goals.

Universal/Mechanical

- Accelerated weathering (QUV, Xenon)

- Ash content* and carbon loading*

- Coefficient of Friction

- Color inspection*

- Compression*

- Density

- Multi-Finger Scratch/Mar*

- Flexural

- Gardner Impact

- Gloss*

- Heat Deflection (HDT, DTUL)

- Instrumented Impact (MAI)

- Melt Flow

- Moisture content*

- Notched and Unnotched Izod Impact

- Opacity*

- Screw Retention*

- Shore Hardness* (A & D)

- Surface Resistivity*

- Surface Tension*

- Tensile Strength*

- Tensile Elongation*

- Vicat Softening Point

Analytical

- FT-IR* (Fourier Transform – Infrared Spectroscopy)

- DSC* (Differential Scanning Calorimetry)

- TGA* (Thermogravimetric Analysis)

Flammability

- UL 94 Series

- FMVSS #302

MISC

- Environmental chamber* (sub-ambient conditioning, thermal cycling)

- Thermoforming* (up to 20” depth of draw)

*not covered by our ISO/IEC 17025:2017 scope of accreditation

“We have used the Farber TIC for many extrusion thermoforming projects, and found Chris and Matt to be extremely knowledgeable and helpful. The ability to make sheet and form parts in the same location provided quick feedback to speed up our development process. I could not recommend them more highly.”