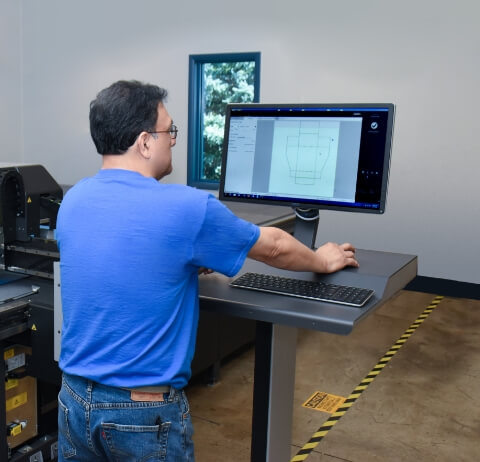

New CAD Table Speeds Time to Market

May 25, 2018

The addition of a Kongsberg C64 automated cutting table is helping Primex Design & Fabrication (PD&F) decrease time to market for its customers. The new high-speed table is capable of handling plastic sheet goods as large as 126” X 126” at thicknesses from 2 to 10 mm. This allows PD&F to complete both prototypes and finished products quicker and more accurately than before.

In conjunction with PD&F’s computer aided design center, Sample Coordinator Debbie Robinson is moving work from concept to production in record times, allowing the company to exceed customer demand and improve throughput. PD&F veteran Robinson was recently promoted to this position in order to manage work flow and ensure customer expectations are being met.

PD&F (formerly Woodruff Corporation) produces a wide range of plastic reusable, returnable and recyclable shipping, storage, point of sale, work-in-progress and internal protective packaging. According to Robinson, “most of our products are custom-designed for very specific needs, so our ability to go from customer request to sample and on to production quickly defines our competitive edge. The addition of this new cutting table greatly enhances that capability.”

As part of the Primex Plastics “One Company” family of companies, Primex Fabrication offers a full production lifecycle from raw materials and design, through prototyping and recycling. Through our “One Company” we can leverage all our resources, including technical development at our John J. Farber Technology and Innovation Center, centralized quality control, faster delivery and a single point of contact for the entire process. All our Business Managers are cross trained and well versed in the entire Primex family of materials, services and expertise, allowing them to offer our customers a more comprehensive approach to their needs.